NPK fertilizer production line.

The NPK fertilizer production line is used to mix single N, P, and K fertilizer to make fertilizer granules. At present, in the NPK fertilizer industry, there are 2 NPK fertilizer processing methods. The first is to turn powdery fertilizer materials into NPK fertilizer granules. And another method is to mix the prepared single N fertilizer, P fertilizer and K fertilizer pellets. In order to meet the commercial production, SX machinery designed the NPK fertilizer making machines for fertilizer plant owners. So, if you want to process NPK compound fertilizer using our machines, you only need prepare the raw materials.

What are raw materials do you need for NPK fertilizer production?

The raw materials of NPK fertilizer production can be classified 2 types.

- Powdery fertilizer. If you bought the NPK fertilizer production line with a granulator, you can use the cheaper powdery N-fertilizer, P-fertilizer and K-fertilizer. And this type raw materials main includes: urea, ammonium sulfate, calcium nitrate, (as nitrogen source); monoammonium phosphate, calcium magnesium phosphate, triple sup-phosphate, (provide phosphate elements); potassium chloride, kainite, potassium sulfate, etc. (as potassium source).

- Fertilizer pellets. In the NPK fertilizer blending line, you can use many different granular fertilizers to produce NPK fertilizer. Such as, urea fertilizer pellets, ammonium sulfate pellets, DAP, MAP, potassium chloride pellets and son on.

How to make NPK fertilizer? – 2 methods for manufacturing NPK compound fertilizer.

What is the manufacturing process options for NPK fertilizer? Here are 2 NPK fertilizer production lines for you to choose. And they are NPK fertilizer granulation line and NPK fertilizer blending line. Next, we will introduce the two production lines for you.

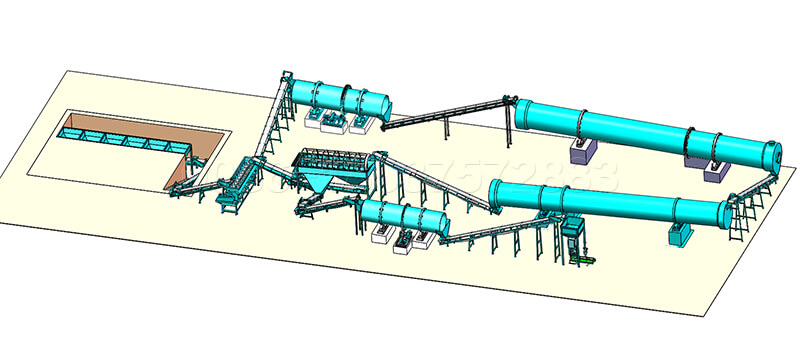

NPK fertilizer granulating line.

The manufacturing process includes raw material pre-treatment and granulation process.

- Crushing raw materials. Crushing the raw materials into fine powder is the first step to produce NPK fertilizer. And here are 3 fertilizer grinders with different capacities for your compound fertilizer plants. They are new type vertical crusher, chain crusher and cage crusher.

- Mixing powdery materials. After crushing, you can use the fertilizer mixer to blend the raw materials evenly. The, you can feed the prepared materials into the granulation process. In addition, if you want to produce NPK continuously, you can use a automatic batching machine.

- Granulation process. Because the quality of the fertilizer pelletizer will affect the NPK fertilizer quality. So, you need to choose the right granulation machine for your plants. Although this is an important step in NPK fertilizer production line, it is not the last step.

- Drying and Cooling. In order to reduce the fertilizer moisture and increase the strength of NPK fertilizer, you need use the fertilizer dryer and cooler to treat fertilizer.

- Screening. When you finish the above steps, there may be some granules not up to the standard of packing. So, you should use the screener to sieve out too small or big fertilizer particles.

- Packing. This is the final step of NPK fertilizer production process. After packing, you can get commercial NPK fertilizer for sale.

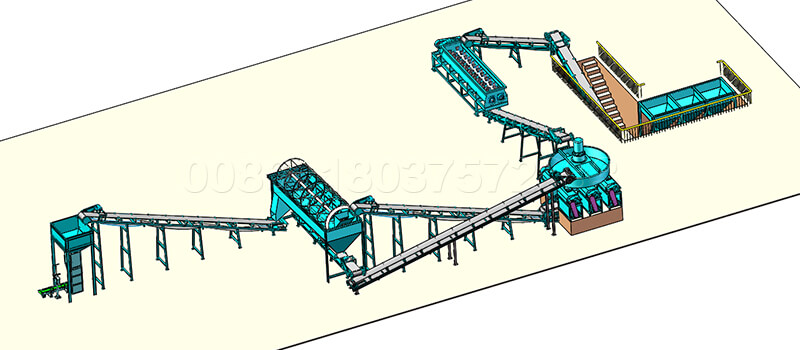

NPK fertilizer blending line.

The NPK fertilizer blending line also is called bulk blending fertilizer production line. And the production process main have batching, mixing and packaging single fertilizer pellets.

- Batching system. The automatic batching system mainly consist of a feeding system, weighing part, stock bin and belt conveyor. And you can use it for precise ingredients.

- NPK fertilizer mixing. After batching, the raw materials will enter the BB fertilizer mixer trough conveyor belt. Then, this machine can mix the NPK fertilizer pellets evenly.

- Packaging machine. When you get the mixed NPK compound fertilizer, you can bag them. In addition, you can also add a coating machine before packaging. Because this coating machine can add a layer of film to the fertilizer to effectively prevent the fertilizer particles from agglomerating.

What is key equipment in the NPK fertilizer production line? -Different granulators for NPK fertilizer plants.

In fact, the key machine is the fertilizer granulator in the NPK fertilizer manufacturing process. Even in the NPK fertilizer mixing production line, we have to use single element fertilizer particles. However, the cost of single fertilizer pellets will be higher than that of powdery fertilizer. Therefore, buying a fertilizer granulator will be the right choice, because it will save you more operating costs in a long time. But how to choose a granulator suitable for your fertilizer plant?

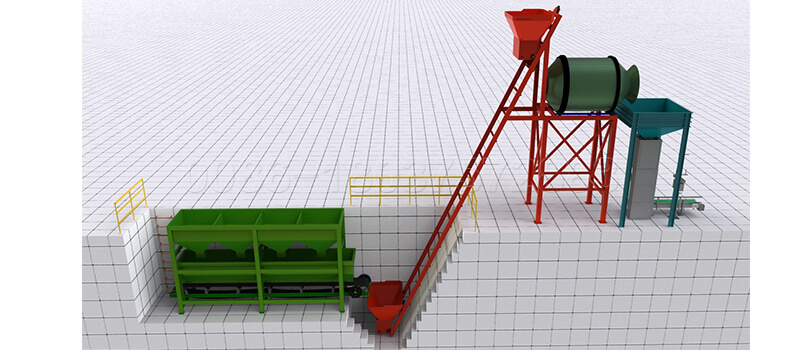

Dry and wet granulator for NPK fertilizer production.

In the NPK fertilizer manufacturing process, if you want to use a dry granulation machine, you need to control the moisture of your raw materials about 10%. And an obvious advantage of using a dry granulator is that you do not need to buy a dryer and cooler. Here, we recommend you use double roller granulator. And it is a multifunctional granulator for various fertilizer making with different shapes.

However, for some NPK fertilizer manufacturers, they want to purchase a wet type granulator. Because using wet granulator will not produce dust. In addition, the wet type granulation machine price is lower than double roller granulator. And, in SX machinery, you can choose right one between pan granulator and rotary drum granulator.

Cost of setting up an NPK fertilizer plant.

Whether it is to build an organic fertilizer plant or an NPK compound fertilizer plant, you need to spend a certain amount of money. The most important cost mainly includes the following parts.

- The site construction cost. Firstly, if you want to produce commercial NPK fertilizer, you need to buy or rent a production site. But this price needs to be calculated based on your local charging standard.

- The machines cost. The precise price of our machines is related to the machines capatities. But you need to consider the purchase cost and operating cost, when you buy any machines. And if you choose a machine manufacturer instead of an intermediate supplier, your purchase cost will be less. What’s more, if you choose a professional fertilizer equipment manufacturer, then the quality of the machine you buy is good, and the energy consumption is low, which will also greatly reduce your operating costs. In addition, SX will also provide the corresponding production technology for free, which will also reduce your cost.

- Manpower cost. When you make NPK fertilizer in your plant, you will need some worker to help you. So, you need spend some money to hire people.

How many people do you need to run your fertilizer plant?

In the NPK fertilizer manufacturing process, you will need some people to operate machines. But the number of the workers depends on the automation degree of the fertilizer production line you bought. Generally speaking, in a small NPK fertilizer plant we designed, you only need 3-4 workers. And a people can feed the raw materials, 2 workers can operate the machines and the last can be responsible for packing NPK fertilizer.

Look here, If you want to learn more about setting up fertilizer plants, you can contact us now. And our professional teams will do our best to help you.

ShunXin

ShunXin