Granulator machine for fertilizer.

Granulator machine is used for fertilizer granulation which is a necessary equipment for every fertilizer manufacturer. You can use it to produce the organic fertilizer, bio organic fertilizer, compound fertilizer and so on. If you plan to buy a fertilizer granulator now, we can provide you with many high-quality granulators. According many years of experience in fertilizer machines manufacturing, we not only provide you with a suitable wet granulation equipment for producing fertilizer, but also can design a dry granulation method machine that meet your needs.

What is wet granulator machine for fertilizer?

First, we will introduce the wet granulators for you. The wet granulator is used to granulate raw materials with a 40%-50% moisture content. With the help of the granulator, the material particles can be aggregated together into special shapes. And in our factory, we have new type organic fertilizer granulator, rotary drum churning granulator, disc granulator and rotary drum granulator. So you can choose a suitable wet granulator machine for your fertilizer plant.

- Disc granulator for fertilizer granulation.

Disc granulator (also called pan granulator) is widely used for producing round pellets of organic or compound fertilizer. The granulating machine adopts the whole circular arc structure, and the granulation rate can reach more than 93%. The design of granulation plate is convenient for intermittent continuous production, which can help you greatly reduce the labor intensity and improve work efficiency.

What is the producing process of pan granulator?

Firstly, you should prepare the raw materials. You can use fermented poultry manure as raw material, such as cow dung compost, chicken poop compost, pig manure compost, horse waste compost, etc. If you need compost equipment for fermenting the manure, you also can buy one in SHUNXIN heavy industry.

Then, you should add the raw materials into disc granulating machine. When the disc granulator starts to operate, the rotating of disc granulator can make raw materials fall down and lift up. The granule gradually become bigger and you can achieve the predetermined fertilizer granules.

In addition, disc granulator can be used for processing compound fertilizer, you only need prepare different raw materials. The process of producing compound fertilizer with disc granulator is the same as that of producing organic fertilizer.

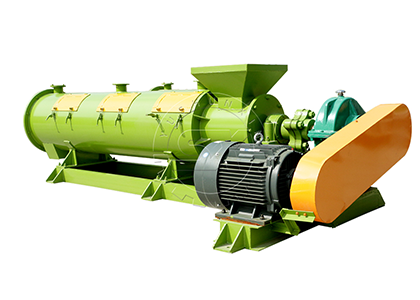

- New type organic fertilizer granulator for sale.

The new type organic fertilizer granulator is the one of wet type granulators. It adopts wet granulation method to process the powered fertilizer into specific shape. If you need a wet type pelletizer in your small fertilizer plant, you can choose the new type organic fertilizer granulator with an output of 1-1.5t/h. In addition, we also have other new type organic fertilizer granulator with other output, our granulator capacity can reach 1 t/h-10 t/h.

The working principle of the new type organic fertilizer granulator.

Our new type organic fertilizer granulator also adpot wet granulation. You can call it stirring tooth granulator, because it has stirring teeth inside, which can produce high-speed rotating mechanical stirring force for granulation. And you can use it to make powder fertilizer continuously achieve the process of mixing, granulating, balling. What’s more, the conglomeration rate can reach about 95%.

The characteristics of raw materials and products when using the new type organic fertilizer granulator.

When you use our new type organic fertilizer pelletizer, you should know these things about raw materials and products.

- The moisture of raw materials is about 30%. And the moisture content of output product is about 15-20%.

- The size of the raw material is preferably 50-200 mesh. In addition, the finished fertilizer granule size is 2mm-5 mm.

- The granule is more beautiful and the bigger size granule rate is less than 10%, if you use our new type organic fertilizer granulator to granulate.

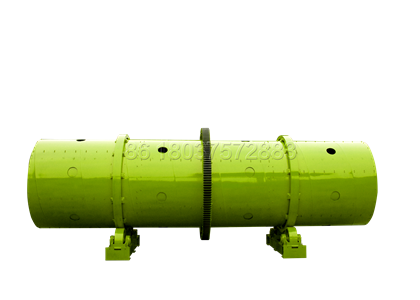

- Rotary drum granulator for manufacturing compound fertilizer.

Rotary drum granulator is the key equipment for manufacturing compound fertilizer. You can buy a rotary drum fertilizer granulator for large-scale production of high, medium and low concentration compound fertilizer. And when the rotary drum granulator work normally, through rotating motion of the drum, the fertilizer pelletize make the raw material particles gather together into balls.

What are features of our rotary drum granulator for producing compound fertilizer?

- Large capacity. Our rotary drum granulator has large capacity. And we can customize the drum granulator with an output of 15-30 t/h for you.

- Long service life. Our rotary drum granulator has the character of long service life for you, because of using stainless steel and is corrosion resistant materilas.

- Wide range of applications. You can use the granulator to produce compound fertilizer, you can also process the organic fertilizer and other pellets.

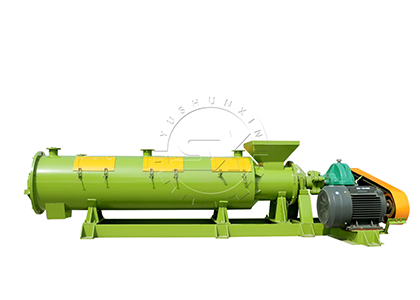

- What is rotary drum churning granulator?

The rotary drum churning granulator is a new granulator developed by SHUNXIN. It is a kind of molding machine which can make the materials into a special shape. It contains two kinds of granulation methods: wet agitation granulation and wet agglomeration granulation. You cannot only use it to make organic granular fertilizers but also to granulate compound fertilizers.

The advantages of rotary drum churning granulator.

- Two combinations of the two kind of granulation makes the pellets more beautiful.

- Our new rotary granulator has a higher granulation rate than a drum granulator.

- Using rotary drum churning granulator can save more energy for you.

How to granulate using dry granulation equipment?

After using a wet granulator to make fertilizer granules, you need to dry them before you pack them. If you don’t want to use wet granulating equipment, we have dry granulators for you. The following is the introduction of two dry granulators for your choice.

- NPK fertilizer double roller extrusion granulator.

NPK fertilizer double roller extrusion granulator is a granulating machine that can granulate at room temperature without drying. And the product produced can be rolled and formed at one time. The NPK fertilizer double roller granulator can not only be used to produce NPK fertilizer, you can also use it to produce other special compound fertilizers, such as PK fertilizer, NK fertilizer and so on. In addition, you can also use it for making cat litter.

The NPK fertilizer double roller granulator has reasonable structure, and has high granulating rate which can be over 95%. And we will debug it before transporting that ensure you can use it normally. More importantly, double roller press granulator for fertilizer production is environmentally friendly, low energy consumption, and no waste discharge.

- Poultry manure fertilizer flat die granulator.

Poultry manure fertilizer flat die granulator is mainly used for pellet processing in the organic (bioorganic) fertilizer and aquaculture processing industry. The granules produced by this machine is cylindrical pellets and these pellets have smooth surface, moderate hardness.

The structure of our poultry manure fertilizer flat die granulator is simple and easy to operate. You can directly put the fermented poultry manure into it to produce cylindrical granules. We have 2mm-8mm diameter molds for you. You can choose the right mold to produce different sizes of organic fertilizer, according to your needs. What’s more, using our granulator can save a lot of energy.

What is the process of using a granulator to produce cat litter?

Using bentonite to produce cat litter is a simple and low-cost method for producing cat litter. If you want to use this method to produce cat litter, the processes you need are: crushing, acidification, sodium treatment, granulating, drying, screening and other processes. In the process of producing cat litter, the equipment you need to use are: chain crusher, double roller granulator, rotary drum screening machine and packaging machine, etc.

Crushing the bentonite.

First of all, the bentonite needs to be crushed into fine particles for later processing. And you can use our chain crusher to help you crush bentonite well.

The acidification and sodium treatment of bentonite.

You can use an acidifier to corrode the bentonite to greatly increase the surface area of the bentonite. Then you should use a sodium modifier to sodiumize the acid-treated bentonite to improve the water absorption and cohesiveness of the bentonite. You can also add other additives such as wood flour, diatomaceous earth to adjust the density and whiteness of the cat litter.

Using double roller granulator to produce cat litter.

You can put the processed bentonite into a double roller granulator and process it into cat litter. And you can produce the different shapes of the cat litter, by choosing different roller sheets of the double roller press granulator.

Rotary dying machine for you.

If you want to get more dried cat litter, you can use our rotary drying machine to dry cat litter.

Package finished cat litter.

You can use our packer to pack the finished cat litter, and then you can make money by selling cat litter in the market.

If you have any questions about cat litter production line, you can contact us.

How to make fertilizer granules more beautiful?

In order to obtain higher economic benefits in the fertilizer market, you should make the fertilizer pellets look more beautiful. In view of this demand, our company has specially developed organic fertilizer polishing machine, compound fertilizer polishing machine and so on.

Our fertilizer polishing machine is a circular polishing device based on organic fertilizer and compound fertilizer granulator. It can make the columnar particles roll to ball, and has no return materials. The organic fertilizer polishing machine has high balling rate, and can make the products more beautiful. So, our fertilizer polishing machine is an ideal equipment for making fertilizer particles more beautiful.

About the latest price of SHUNXIN granulators.

After you know the performance and usefulness of various pelletizers, you may be most concerned about their prices. You must know that different types of granulators use different production technologies, and the materials used in different equipment are also different. Even the same type of granulator, due to the difference in capacity, their prices are also different. But the price of all fertilizer granulators of SHUNXIN is reasonable, and they are all ex-factory prices.

If you want to know the latest price of SHUNXIN granulator machine for fertilizer, you can contact us now, or send us an email. In the email, you can tell us that you want to know the latest offer for granulator. Then we will provide you with detailed prices of the granulators and considerate service for free. In addition, you can get in touch with us too, if you want know about granulators for fertilizer.

ShunXin

ShunXin