Medium scale composting and small scale composting.

With the development of industry, local governments pay more and more attention to environmental protection work. So the traditional composting model is no longer suitable for the current fertilizer industry, and more and more people choose to develop green fertilizer.

Some beginner chooses to start small scale composting factory. However, some person are optimistic about this industry, so they choose to start from a medium-scale composting plant. But most small fertilizer manufacturers choose to expend their scale later. This means they need the medium-sized equipment to meet production needs. Because compared with small-scale composting machines, mid-sized composting machines have an increased daily processing capacity and higher work efficiency.

What are the preparations for medium scale composting?

When you determine to build a medium scale composting plant, you should have the following plan.

- Raw materials. Know the raw materials, humidity and scale, etc. Because these will affect your next choice.

- Location of the factory. Generally, organic fertilizer plants are far away from industrial areas, which can avoid pollution to residents’ lives and other plants. And you have to consider the transportation cost of raw materials, the power and water supply in the factory.

- Fermentation process and fertilizer equipment. Different composting processe uses different machine, and plant area and layout are different too. For example, tank fermentation only needs less place. But stack fermentation needs more space. So you should choose right composting equipment.

Composting machines for medium scale manure.

If you have written your plan, then you should prepare the equipment. However, there are many composting turners in the market. And according to the daily processing capacity of the equipment, they can be divided into large, medium and small scale compost turners.

Generally, according to the technical parameters of the machine, we can calculatethe organic fertilizer turning machine size. And the mid-sized machine can turn 600-1200 m3 of materials per hour (equivalent to the tireless workload of about 100 people at the same time). Among them, compost turning machines for mid-scale composting factory are as follows.

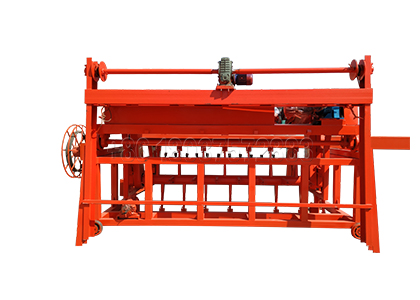

Medium-scale Groove type compost turner with a processing capacity of 800-1000 m3/h.

You can customize a medium-scale groove type compost turner with the width of 3-4 meters, and the turning depth of 0.8 meters. It can turn 800-1000 m3 organic waste per hour, which is equivalent of 70-80 workers turning at the same time. Therefore, most organic fertilizer plants, compound fertilizer plants like use it.

The machine is suitable for aerobic fermentation. And it has the advantages of turning evenly and working high efficiency. This is related to its high-quality components and compact structure. When it works, trough the electric transmission device, the stirring gear can realize lifting and rotation. Then stirring teeth crush and turn the materials in the fermentation groove.

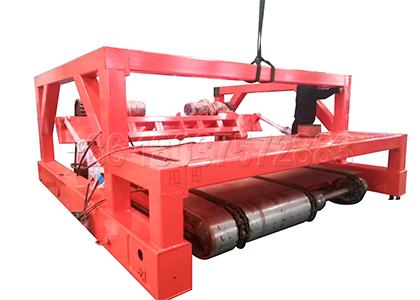

Mid-sized wheel type compost turner with a processing capacity of over 1200 m3/h.

Wheel type compost turner is suitable for your medium scale composting plant. And the turning depth of mid-sized wheel type compost turner is 1.5 meters, and the turning span is 10-15 meters. Its minimum processing capacity is more than 1200 square meters per hour.

The machine adopts a middle chain transmission mechanism to drive two large-diameter turning roulettes, it can turn the manure symmetrically and without dead angles. In the case of deep stacking materials, the energy-saving transmission mechanism uses less power to complete the high-depth, large-span turning operation. Its hydraulic lifting system can automatically lift the turning plate to ensure that the equipment can move without obstacles.

Chain plate type compost turner is used for the medium scale composting plant.

Medium scale chain plate type compost turner is another groove type composting machine you can buy, which can dispose 900 m3 of organic waste per hour.

This machine adopts hydraulic device to turn the pile depth up to 2 meters. The vertical height of the material can reach 2 meters, and material stays in the air for a long time and it can be in close contact with the air. You need not add additional aeration devices. In addition, the medium scale chain-plate type compost turning machine is designed reasonably, the motor consumes less power, and the transmission adopts a high-quality hard-surface gear reducer, which has low noise and high efficiency.

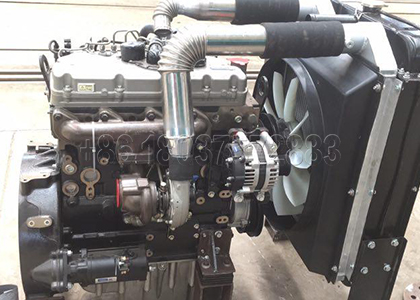

How is the medium scale crawler type compost turning machine?

The multifunctional medium scale crawler type compost turner will be meet your needs, if you don’t want to build a groove when composting manure. Our crawler type compost turner working speed can be 6-10 m/min. And its processing capacity can be 1000-1200 m3/h. In addition, this medium scale composting machine adopts full hydraulic power design, there is basically no mechanical wear, the failure rate is very low, and the maintenance is very little.

Characteristics of medium crawler composting machine

The compost turner adopts a full hydraulic operating system, a tie-rod steering wheel operation, a crawler-type walking, and a high-horsepower diesel engine. And its stacking width can reach 2.6-2.8 meters, the height can reach 1-1.4 meters. In addition, it can achieve rapid temperature rise, rapid deodorization, sterilization (can kill insects, eggs, germs, etc.), and rapid fertilizer formation. Therefore, it is faster and more efficient than other mechanical fermentation methods..

Organic fertilizer fermentation pot with a processing capacity of 600-800 m3/h.

Do not you like the above composting equipment? There is organic fertilizer fermentation tank, you will like it. Medium-sized organic fertilizer fermentation pot can treat 600-800 m3 organic manure per hour. And it has the characteristics of low energy consumption, low pollution and low operating cost, which makes it not only favored by small organic fertilizer manufacturers, but also favored by medium-sized fertilizer companies.

The working process of medium-scale fermentation pot

It mainly adopts the principle of aerobic microbial aerobic fermentation. Under a certain temperature, humidity and sufficient oxygen environment, decomposing bacteria multiply rapidly and decompose organic matter. At the same time, a large amount of heat is released, which increases the temperature in the tank.

And the temperature above 60℃ can kill harmful bacteria, pathogens, parasite eggs and other harmful substances in the feces. With the continuous addition of fresh livestock and poultry manure, the microorganisms in the tank continue to circulate and multiply. So that you can realize the harmless treatment of manure.

How to speed up composting with medium scale compost turner?

In a medium-sized organic fertilizer plant, when composting organic materials, it is a wise choice to use a machine to turn the pile. Because it can effectively improve the degree of fermentation and dewatering of organic waste. The composting machines mainly relies on its own component design to turn, stir, and crush the raw materials. So that the organic materials are better exposed to air and fermented, thereby increasing the utilization rate of organic waste.

What kind of medium scale compost machine is of good quality?

When everyone buys a product, the most important thing is its quality. Similarly, every medium scale fertilizer manufacturer also wants to buy high-quality medium scale compost machine. Because the quality of production equipment affects your development speed, you must pay attention to a few points when choosing medium scale composting equipment:

- Produced by large manufacturers.

Large-scale equipment manufacturing plants have been established for a long time, are experienced, and have their own professional and high-quality team. Zhengzhou SHUNXIN engineering equipment Co., Ltd. was established on September 23, 2005. We have a professional team composed of experts, professors and senior engineers. And we have our own brand and our high-quality equipment are popular both at home and abroad.

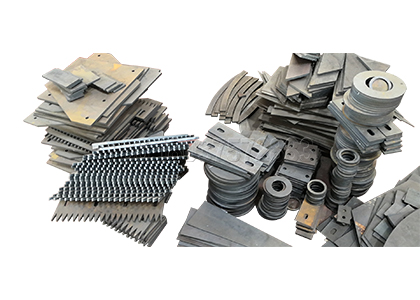

- Product specifications.

A good product must first meet the standards, especially for production machine. A good medium scale composting machine must meet all the indicators and is complete in specifications and quality. All medium scale composting machine of SHUNXIN not only meet all the indicators, but also all are complete in specifications and quality.

- Good after-sales service.

A good after-sales service can help you solve a lot of worries. Our company(SX) has realized one-stop service for design, manufacture, installation, debugging, technical training. After customer’s machine is put into operation, we will follow up and visit irregularly to understand the machine operation, production capacity, service condition of wearing parts and other problems encountered by the customer at the stage, so as to solve the problems immediately and give more technical guidance.

Using the medium-scale composting machine correctly.

The correct use of medium-scale composting machine has many advantages. The one can ensure the normal progress of the entire composting process. And it also can protect equipment well and prolong the use time of the equipment.

When we transports the composting equipment to the customer’s fertilizer plant, we will appoint special personnel to train the equipment operators of the fertilizer plant. This approach can ensure that the customer can operate the equipment correctly in the follow days, so as to quickly put into production and obtain benefits.

ShunXin

ShunXin