Commercial composting equipment.

Commercial composting equipment is the key machine for producing organic fertilizer. When we manage animal manure, the composting method now is aerobic fermentation. However, in the commercial composting process, with the decomposition of microorganisms, the temperature of the compost pile will increase and the oxygen content will decrease. In order to get good organic fertilizer, you need to adjust the temperature and increase the oxygen content. So you need to use a composting machine to turn the pile. And there are 3 types composting equipment: windrow composting turner, in-vessel composter and groove type composting machines.

3 types commercial composting machines for sale.

SX Heavy Industry, with 30 years experiences, designed and produced 3 kinds of composting equipment for your commercial organic fertilizer plant. And they are windrow turner, in-vessel composter, groove type composter.

- Windrow turner.

In SX, windrow type composting equipment includes: crawler type compost turner, self-moving type compost turner.

Firstly, the crawler type compost turning machine is the most widely used composting machine. And we adopts advanced technology to design it. We use full hydraulic operating system and a soft start type clutch, so that it is easier to operate and save resources. In addition, we installed a front hydraulic push plate, so there is no need to waste manpower and time to sort the compost pile.

Next is moving type compost turner. It is the special machine for biofertilizer production. And the self-moving composting machine adopts a four-wheel walking design, which can be driven forward, backward, and turned by one person. When it works, it rides on the long strip of fertilizer that was piled up in advance. Then the rotating knife shaft hung under the frame performs the mixing, fluffing, and shifting of the fertilizer-based raw materials. In addition, it can run in an open field or in a workshop.

- Groove type composting machine.

If you want to make full use of land resources, our trench type composting machines will be a good choice. This type turning machine has the characteristics of large processing capacity and high degree of automation, which is suitable for the centralized treatment of waste in medium and large-scale farms. In addition, groove type composting can prevent odor from polluting the environment at a certain extent. Because it always works in a closed fermentation workshop.

And if you want buy one, we have wheel type compost turner, new groove type compost turner and chain plat type compost turning machine for you to choose. Among them, the best we sell are wheel type composter and new groove type compost turner are sold well, because their reasonable prices, high work efficiency and low operating cost.

- Organic fertilizer fermentation pot.

In addition to the above two types composting machines, wo also have in-vessel composter (organic fertilizer fermentation tank).

Our fermentation pot adopts intelligent high temperature aerobic fermentation technology. When you put raw materials with 55%-65% water content, the organic materials begin to fermentation in the tank. Under the function of aerobic bacterial, raw materials can be decomposed thoroughly and become organic fertilizer. What’s more, our organic fertilizer fermentation pot solves the problem of raw materials harm to the environment and people, and also solves the problem external temperature affecting the fermentation cycle.

How to make organic compost commercially? – A complete composting line.

Can you start composting with just a composting machine? For a commercial compost plant, the composting equipment is the key machine, but not all. Because, you need to dispose raw materials before fermentation and manage organic fertilizer after composting. So, what other machines do you buy for your fertilizer plant? Here is a complete composting line for your reference.

- A complete composting line.

A complete composting line includes: dewatering machine, grinder, mixer, composting turner and screening machine, belt conveyors. Next, excepting composting machine, we will tell you the role of other machines in the composting line.

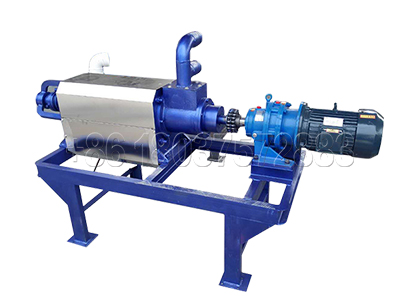

- Dewatering machine. Because the right moisture is about 55% in the commercial composting process. So, if your raw materials moisture is too high, you need use dehydrator to reduce the water content.

- Grinder. Its role is to process large pieces of raw materials. Because large lumps can affect the permeability and quality of the compost.

- Mixer. In order to mix the raw materials and fermentation bacteria in your commercial compost plant, the mixer also important machine for you.

- Screening machine. When you get finished compost, you can use our fertilizer screener to remove the stone or big lumps.

- Belt conveyors. They are key equipment linking each machine above, and transport materials from a place to another.

What is the commercial composting machine price?

Just like we buy other things, we must care the price. How much a commercial composting machine?

Here we mentioned 6 composting machines, they adopt different technologies and production process. For instance, crawler type compost tuners adopt full hydraulic operating system, so that its price will higher than self-propelled type composter. And using different accessories will also affect the machine price. We take our wheel type composting equipment as an example, the bearings it uses are of the famous SKF brand. Therefore, its cost is higher than other equipment. But if you divide the total price by the number of used years, it is cheaper than those produced by other companies.

Now our composting machines are all sold with ex-factory price, if you wan to get a high-quality composter, you can contact us.

What raw materials can be disposed in your commercial fertilizer plant?

Composting process is also waste recycling process. Most organic materials can be disposed with our composting machines. Common raw materials are as followings:

- Poultry manure: chicken poop, pig manure, cow manure, sheep manure, horse manure, rabbit manure, etc.

- Crop stalks: Crop stalks are one of the important fertilizer varieties. Crop stalks contain essential nutrients for crops such as N, P, K, Ca, s, etc.

- Cake fertilizer raw materials: rapeseed cake, cotton seed cake, bean cake, sesame cake, castor cake, tea seed cake, etc.

- Other raw materials: filter mud from sugar mill, biogas residue, tea dregs, etc.

If you have other raw materials, you can contact us for consultation. And we have professionals to provide you with professional solutions.

Commercial composting equipment maintenance manual.

How to prolong the service life of your commercial composting equipment? Here we provide you a maintenance manual for you.

- Check items before use:

- Check whether the fasteners are firm and whether the bearing clearance of moving parts is appropriate. The inappropriate places should be adjusted in time.

- Add butter to the bearing seat and check the oil level of the reduction box;

- Whether the wire connection is firm.

- Maintenance after use.

- Turn off the power switch.

- Add lubricant to each lubrication point.

- Remove the residues and remaining materials on the machine and surrounding sites.

- Weekly maintenance items

- Check the oil quantity of the reduction box and fill enough gear oil.

- Check the contact condition of each contactor in the electric control cabinet, if damaged, replace it immediately.

- Regular inspection items

- Check the operation of the motor reducer, if there is abnormal noise, heat, etc., it should be shut down immediately for inspection.

- Check the wear of each bearing, if it wears too much, replace it.

If you want to know more details of commercial composting equipment, please contact us.

ShunXin

ShunXin