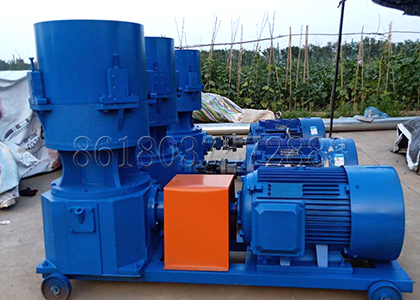

Flat die granulator for you.

Do you want to have a latest granulator in your organic fertilizer plant? You would like produce fertilizer pellets with flat die granulator. And you can also use it to process feed for the breeding industry. More importantly, you can save a lot of energy in granulating process.

The flat die granulator produced by SHUNXIN can meet all your requirements above. Because it apply the latest technology. And it breaks through the traditional organic granulation process. You can use it to granulate various organic matter after fermentation. Moreover, the raw materials do not need to dried and grinded before granulation. In addition, it can process cylindrical granules by consuming less energy.

And you can use the flat die granulator alone, or form an efficient organic fertilizer production line with other equipment.

What are the special features of the flat die granulator?

The flat die press granulator is the latest technology product in our company. And we adopt many special designs to produce the flat die granulator. You can know the granulator more by reading the following words.

- The pressure rollers. The pressure rollers of the flat mold granulator is arranged evenly and the operation is stable. The design can improve your production efficiency.

- Adopting the central spiral compression structure, the internal spacing of the mold is adjustable. Therefore, the flat die granulator is not only suitable for different raw materials, but also ensures the quality of the organic fertilizer granules you produce.

- Two sides of the roller have the same linear speed. To a certain degree, this design can help avoid unnecessary friction between the die and roller. And it can alao reduce energy consumption as well as production expenses.

- A variety of molds for your choice. We have different porous molds with a 2-10mm. So that you can choose a suitable mold according to your needs.

- The purity of the organic fertilizer pellets can reach 100%. In addition, the produced particles have a low moisture content and are easy to store. And the pellets can remain intact for a long time in water, which greatly improves the utilization rate of materials.

What is the producing process of the flat die granulator?

Understand the producing process of the flat die granulator, you can make better use of it to obtain higher economic benefits.

Our flat die pelletizer depends on mechanical movement to granulate. It uses belts and gears to transmit power to the main shaft. Then the main shaft drives the pressure roller, cutter and scraper to work. When the granulator is working, the roller shaft rotates with the main shaft. And the roller rotates under the action of friction, so that the material is squeezed to form particles. When the pellet reaches a certain length, the cutter at the bottom of the die will cut the pellet and discharge it to the pelletizer.

How to treat chicken manure with a flat die granulator?

Chicken manure contains high levels of nutrients. Usually we have two ways to deal with chicken manure.

- The first method of treat chicken manure by a flate die granulator.

You can deal with chicken manure as feed. The crude protein in chicken manure is about 28%, crude fiber is about 15%, crude fat is about 3.5%, and it is rich in B vitamins and various trace elements. Therefore, chicken manure is generally regarded as an economical protein feed, which can replace part of the feed for the breeding industry. Now, you can use the chicken manure flat die pelletizer to process chicken manure into feed easily.

You only need add chicken manure powder and other ingredients into flat die pellet mill, then start it to granulate. This way of chicken manure management can bring you good economic benefits.

The second way of disposing chicken waste with flat die granulator.

Turning chicken manure into organic fertilizer is a good way. Because chicken manure is rich in nitrogen, phosphorus, potassium and other good organic matter. In order to use this method, you need have a chicken manure flat die pelletizer production line. And our flat die granulator organic fertilizer production line includes: groove type compost turning machine, rotary screening machine, flat die press granulator and packing machine. The following explains why use these devices.

- Groove type compost turning machine. Because you must use the fully fermentation chicken manure to make organic fertilizer, you need to compost chicken manure before granulation. When you ferment the chicken manure, the groove type compost turner can help you turn chicken waste. So that you can get high-quality chicken manure compost. Then you can make high quality organic fertilizer.

- Flat die press granulator. With the help of flat die granulating machine, you can get organic fertilizer pellets easily.

- Rotary screening machine. The rotary screening machine can not only help you screen the big lump materials or stones, but also can help you get good fertilizer granules.

- Sigle bucket automatic packing scale. The packing machine can help you pack fertilizer easily, because of its quantitative packaging syetem.

This way for processing chicken manure is very simple, but the efficiency is high. Compared with other organic fertilizer production lines, you need not use drying equipment. So that you can reduce some investment costs. What’s more, you can use this producing method to dispose other organic waste, such as pig manure, cow dung, sheep waste and other animal waste.

4 precautions of using flat die granulator.

When using a flat die granulator, you should remove hard objects such as stones and iron blocks in the raw materials. Because these hard materials will damage the parts of the granulator.

The moisture content of raw materials should be controlled between 20%-40%, when you use flat die fertilizer pelletizer for granulation.

When you find that the particles are broken or not compacted, you should reduce the formula of crude fiber materials to less than 50%.

When granulating, the die of the flat die granulator and the molds are prohibited from contacting. If you find that there is no raw material, you should immediately cut off the power supply of the granulator. In addition, if the granulator does not granulate during the granulation process, you should remove the mold. After opening the hole, you can reproduce the addition of raw materials for granulation.

If you have other questions, you can contact us and we have professional salesmen to help you solve them.

How much can you buy a latest flat die granulator?

Now, there are various flat die granulators on the market. You must see the model and specifications of the flat die granulator, before you pay for it. Because the prices of flat die granulators of different specifications are different. Generally speaking, the higher the output of the pelletizer, the higher the price.

In addition, the prices of flat die granulators produced by different manufacturers are also different. Some manufacturers’ flat die pelletizers are sold with the help of third parties, and the prices are slightly higher. And some manufacturers sell it by themselves, and the price is generally the ex-factory price which is lower. For example, SX heavy industry is the later, our plat die granulators are sold to customers at factory prices.

If you want to buy a latest flat die granulator now, you can contact us and our latest quotation will be provided to you for free.

ShunXin

ShunXin