Fertilizer Production plant.

Fertilizer production plant is where fertilizer is produced. Now, there are so many fertilizer manufacturing plants all around the world. Why? As you know, fertilizer is one of the material foundations of agricultural production. If you want to get good agricultural products, good fertilizer is essential. And with the improvement of people’s living standards, people’s requirements for fertilizers are getting higher and higher. Especially in recent years, organic food has received more and more attention. Therefore, the demand for organic fertilizer has also increased. Starting an organic fertilizer production plant becomes a good investment idea.

What are the main contents of the business plan for establishing a fertilizer plant?

Investing in a fertilizer plant is indeed a very promising project, but establishing a fertilizer plant is not an easy task. So, if you want to start a new fertilizer production plant, you should have a detailed business plan. And these main contents should be written on your business plan.

Write down what type of fertilizer is produced.

You have to decide about which product to be manufacture at the beginning. You can determine your production direction in accordance with your raw material. For example, your raw material is cow dung, you can produce organice fertilizer from dairy manure.

Write down where will the business be located.

If you can choose a good place to start your fertilizer production plant, it is will be a money-spinning business. Mainly rural areas with abundant agriculture and suburbs of towns and cities are ideal for setting organic fertilizer plants. In addition, you should consider the transportation cost of the raw materials.

Write down how many tons of fertilizer do you plan to produce each year.

Production capacity planning determines what production technology and production equipment you need to use. There are small-scale, medium-sized and large-scale production lines and other equipment. You can choose one for starting your fertilizer production plant.

Write down what kind of fertilizer production machine to buy.

Choosing the right fertilizer production equipment is very important for a new fertilizer production plant. It affects your production speed and product quality. So you should buy the right machines.

What fertilizer is produced in your fertilizer production plant?

Once you read the business plan, it’s time to take action. In order to carry on your fertilizer business long-term and sustainably, you should choose to produce fertilizers with promising development. And when you investigate the fertilizer industry, you can find that the more promising fertilizers now include organic fertilizer, bio-organic fertilizer, and compound fertilizer. Therefore, in the fertilizer production plant, you can not only make compound fertilizer with nitrogen, phosphorus and potassium, but also product organic fertilizer and bio organic fertilizer from a lot of organic materials. In addition, the production of organic fertilizer can not only effectively treat organic waste, but also protect the ecological environment.

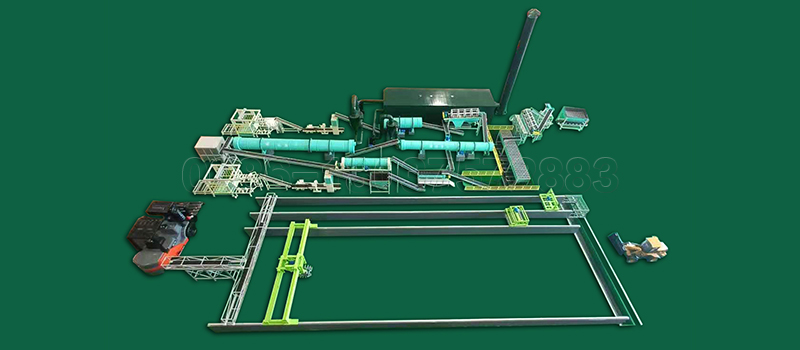

3 types of hot fertilizer production lines provided by SHUNXIN.

Fertilizer manufacturing line is important for fertilizer production plant and every plant has its own production line. When you are ready to engage in fertilizer production, SX provides 3 types of fertilizer production lines for your reference. You can apply these fertilizer producing lines to make the compound fertilizer, organic fertilizer and bio organic fertilizer.

- The production line is widely used in compound fertilizer.

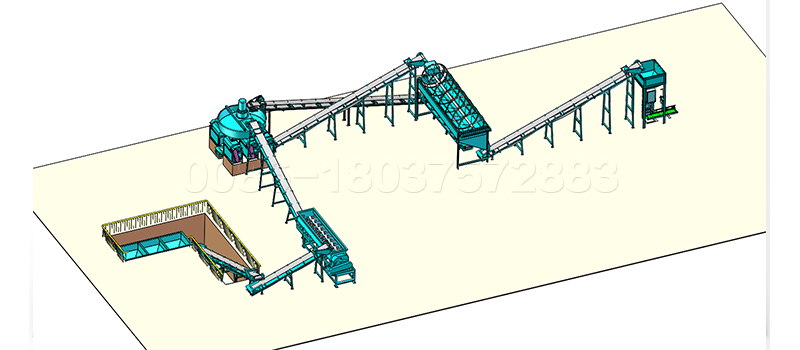

Our compound fertilizer production line can produce many types of compound fertilizer, and the products produced all have good quality. The production line includes: raw material crushing, raw material batching, raw material mixing, fertilizer granulating, particle drying and cooling, granule screening, product coating, and finished product packaging. If your raw materials are Nitrogen, Phosphorus, Potassium and other substances, you can use this production line to efficiently produce compound fertilizers and get more profits.

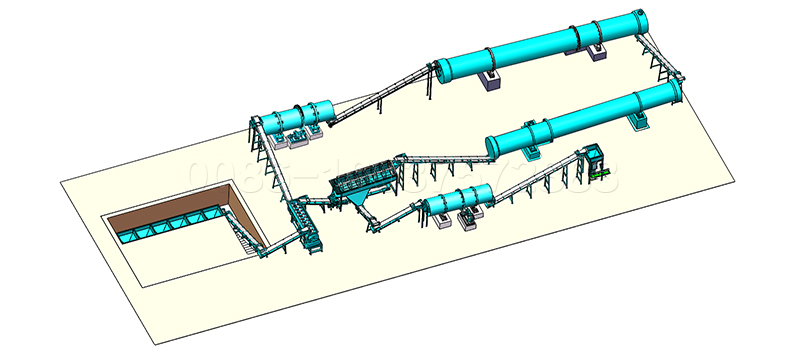

- Fast-growing organic fertilizer production line for you.

In recent years, the development of organic fertilizer has been getting better and better. And more people have begun to choose to produce organic fertilizer for economic benefits. If you have pig manure, chicken poop, cow dung, sheep manure, mushroom waste, crop straw and other organic waste, you can choose our high-efficiency organic fertilizer production line. Generally, the organic fertilizer production process includes: the organic martials pretreatment, compost fermentation, post-processing. You will use our crushing machine, mixer, compost turning equipment, granulator, screening machine and so on.

- A new type of fertilizer production line-biological organic fertilizer production line.

As a new type of fertilizer, bio-organic fertilizer is an organic fertilizer containing functional microorganisms. And its manufacturing process is not difficult. When you add suitable microorganisms (or bacteria) in the process of producing organic fertilizer, you can get the bio-organic fertilizer. But if you add the microorganisms before the granulating the organic fertilizer, you need mix the powdered fertilizer and microorganisms evenly, then you can make the granular bio-organic fertilizer. When you add the microorganisms in the granular organic fertilizer, you need use rotary coating machine to get granular bio-organic fertilizer.

How much fertilizer equipment do you need in your fertilizer plant?

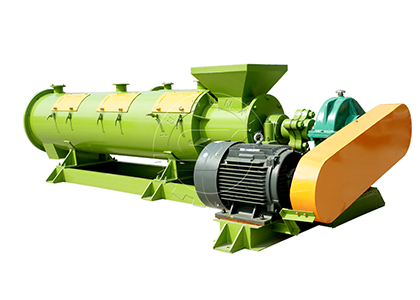

If you want use the above production line, you need to buy some fertilizer equipment. And the main fertilizer production machines for your fertilizer factory includes: fermentation equipment, fertilizer granulator, crushing machine, mixing equipment, rotary drum drying machine, rotary drum cooling machine, rotary screening machine, packing equipment and belt conveyor and other auxiliary equipment. These machines can help you realize the commercial and automated production of fertilizer. In addition, you can buy these fertilizer machines in SHUNXIN and we can provide you with high-quality fertilizer equipment.

How to deal with organic waste using our machine?

When you deal with organic waste, you can use our solid-liquid separator machine to dispose the raw materials with high moisture, then you can compost them. In order to speed up the fermentation, you can also use our wheel type compost turner or crawler type compost turning machine.

Equipment for producing granular fertilizer.

After you treat the raw material, if you would like to get granular fertilizer, you need to use fertilizer pelletizer. In addition, there are a new type vertical crusher, horizontal mixer and new type organic fertilizer granulator for you to choose.

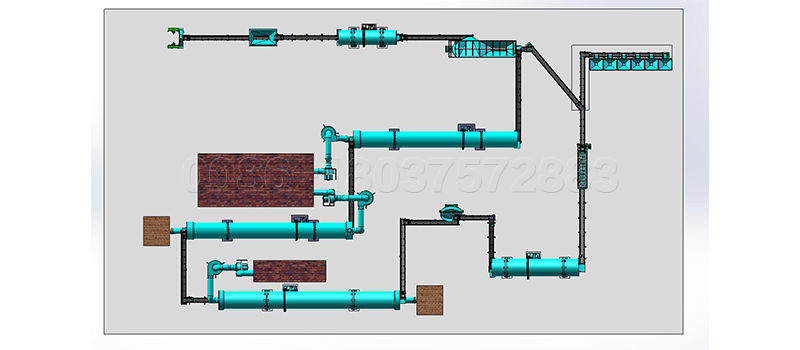

Use dryers and coolers to reduce the moisture content of fertilizers.

After granulation, you need rotary drum drying machine and rotary drum cooling machine to reduce the moisture content of the fertilizer. The purpose of this step is to facilitate the storage and transportation of fertilizer.

Rotary screening machine.

Before bagging the finished fertilizer, you should use our rotary screening machine to screen out the unqualified products.

How to ensure fertilizer quality in your fertilizer production plant?

Because good quality fertilizer can really improve the soil and increase the yield of crops, so you have to make sure the fertilizer is of high quality. So that you can get good economic benefits. And there are some tips you should know as following.

- Firstly, you should ensure the raw materials are safe and you have to remove debris and harmful substances in the raw materials.

- Second, you should use high-quality production equipment. Good fertilizer equipment will not destroy the organic matter of fertilizer, and the fertilizer produced meets national standards.

- Finally, when storing fertilizer, you should take care to prevent the fertilizer from caking and deterioration. Because agglomerated fertilizer will affect the fertilizer efficiency. And you cannot the spoiled fertilizer. Because it not only loses its original effect, but may also cause other harm to the soil.

If you want to know more information of fertilizer production lines, you can contact us anytime.

ShunXin

ShunXin