Disc granulator is a fertilizer pelletizer, you can use it in organic fertilizer plants or compound fertilizer factories.

- The work principle of this type granulator machine.

The plate granulator uses centrifugal force to agglomerate powdered fertilizers. In general, the longer the time, the larger the fertilizer particles formed.

So, it can be used to produce organic, bio fertilizer and compound fertilizer from various raw materials, such as, poultry manure and other organic materials, nitrogen , phosphate , potash (chemical materials) and so on.

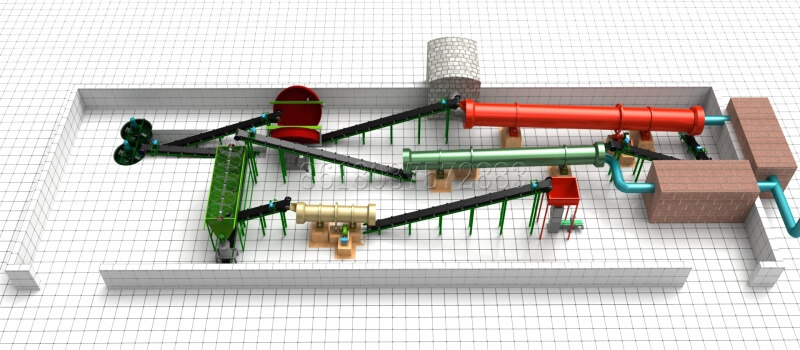

Compound Fertilizer Production Line with Disc Granulator

-

What is the particles size of raw materials can be fed to disc granulator?

Generally speaking, the size of the raw material is about 50 mesh.

-

The raw materials moisture in pan granulation process.

Before using pan granulator pelletizing, you need to make the raw materials moisture content aabout 30%. Because the water content will affect the fertilizer pellets size. And if your raw materials so wet, the finished fertilizer granules will be bigger. But if the materials so dry, you need to add some water into the granulation machine.

Poultry Manure Fertilizer Granular Fertilizer Made By Pan Granulator

-

How many time is it from powder to pellet?

Using the pan granulation machine, the powder fertilizer turn to granular fertilizer only need 5-8minutes.

In addition to produce fertilizer particles, to a certain extent, the granulation equipment can make all powder into pellets.

And after granulating, the finish product size can be 1-8mm. In addition, the moisture content of the fertilizer granules is about 20%. If you want to sell your fertilizer or store them, you have better to use the rotary drum dryer to reduce the granules moisture content, and make water content below 10%.

If you want to learn more details about the pan granulation machine, such as its structure, the work process and so on, you can look at this page:Pan Granulator

Or you can contact us by email and call us.

ShunXin

ShunXin