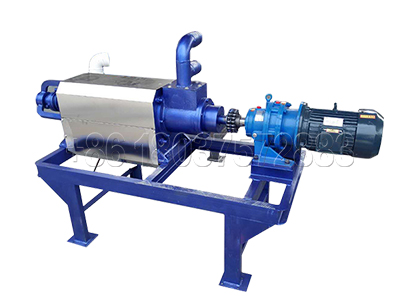

Dewatering screw press machine for sale.

Dewatering screw press machine is a kind of dehydrators for processing organic raw materials. It adopts continuous screw extrusion technology to separate the organic waste. And it can separate the solid and liquid from the material with high water content. And after processing by our screw extrusion dehydrator, the water content of organic waste becomes low, only 40%-50%. Then, you can use the separated organic solids to further produce fertilizer or commercial compost for sale. Therefore, this way will not only help you deal with organic waste, but also have considerable economic income.

What are the main components of the dewatering screw press machine?

For making best use of our dewatering machine mainly, you can learn the machine design.

Our dewatering machine consist of six parts: the host, transfer pump, electric control box, elector motor, reducer, rubber hose.

- The host. The host includes screw shaft, filter screen, feeding inlet, discharge port. And you can choose different screen diameters to meet your needs.

- Transfer pump. In order to improve dehydration efficiency, we use no-clogging design to prevent the transfer pump clogging.

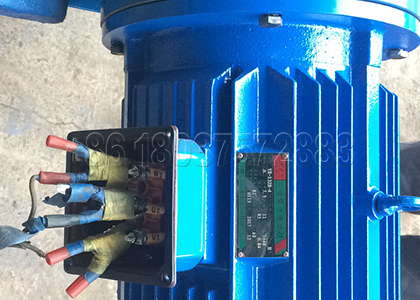

- Electric control box, elector motor, reducer. They are all high-quality products. So that can ensure you can use it safely.

How does the dewatering screw press machine work?

Before you use the dewatering machine, you can learn about the machine working principle as following.

- When the dehydration work starts, the solid-liquid mixture will enter the dehydrator host through the transport pump.

- Then through the screw extrusion, the machine can separate liquid and solid. And you can dischare the liquid from the screen. While the solid material is continuously pushed to the outlet through screw extrusion.

- At the same time, the machine clean its filter layer automatically.

In addition, for controlling the discharging speed and water content, you can adjust the weight block below the host.

The advantages of dewatering screw press machine.

SHUNXIN dewatering screw press machine has many advantages. And here we list some for you to better know our dehydration machine.

- Wide application scope. The dehydrator is suitable for processing various organic waste. You can not only use it to dispose animal manure, but also can process high concentration organic waste, etc.

- Low investment and high return. You can use the dewatered organic materials to produce highly profitable products, such as organic fertilizer, bio-organic fertilizer and so on. But the cost of the dewatering machine is lower.

- Long service life. The host is made with ductile iron, the crew shaft and filter screen all use stainless steel design. So it has a long service life for you.

- Automatic operation. Because the entire dehydration process is automatic, you do not need hire workers to operate it.

- The benefit is much higher than the cost. If you have suitable raw materials, it is very wise for you to invest a screw press dehydrator.

ShunXin

ShunXin